Inline Static Mixers

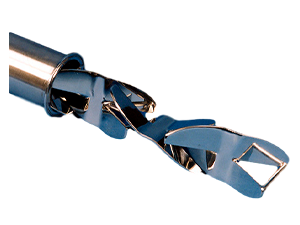

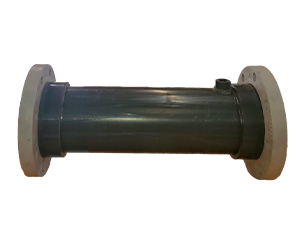

The Komax industrial inline static mixer provides an energy-efficient solution in the process pipeline industry by effectively mixing process fluids to produce a homogenous output. The process stream flow provides all the energy required to complete the mixing with no motors, moving parts, or auxiliary power needed, eliminating excess maintenance and downtime within the existing pipeline.

Benefits of Custom Inline Static Mixers

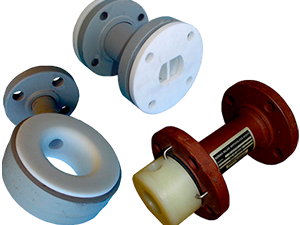

Our customization capabilities at Komax Systems give our customers a multitude of options for their existing systems. We can design and build custom static mixers for our clients that meet each unique system's demands and requirements to ensure a seamless fit and a top-tier end product is achieved. Customers may customize their industrial static mixer length up to 72", pick of construction material, choice of open or closed channel, element customizations, addition of injection ports, and choice of end connections, including flanged, threaded, plain, and DIN ends.

Throughout the entire process our customers have our skilled sales engineers right by their side available to offer any recommendations or useful insight that may be needed to achieve the desired end product.

Our Custom Product Process

Getting a Komax Systems product for your industrial process is simple! To get started, give us a call or submit a quote via our website to get your quote started.

Once we receive your request, our sales engineers will populate a unique quote specific to your custom design and your process' needs. Once the quote is finalized it is then paired with a drawing mock-up of your unit.

As soon as the quote and drawing are approved, your unit is then off to fabrication. While your unit is being manufactured you are kept up to date on its progress and you will be notified once your new Komax Systems product is on its way to you!

Submit Your Request

Fill our out easy online form and get in touch with us!

Talk With Our Experts & Get a Quote!

Our experts will fine tune your quote to meet your projects specifications.

Get a Custom Design of Your Product

Get a sense of what your product will look like and how it will fit into your system.

Fabrication and Shipment of Your Order

Once approved we have the unit manufactured and shipped off to you!

Size

Our industrial static mixers are available in a range of sizes and materials. Depending on the line size, application, and process flow the static mixer is typically designed between 1”-24”. Though Komax custom-designed static mixers have gone up to 72” and any length in between. Depending on the line size and flow conditions our engineers at Komax Systems will design the inline static mixer to perfectly fit the unique process application of your system to attain the desired results. During this calculation, the static mixer length and number of elements will be determined to ensure the proper design and construction are developed for your already existing system.

Industries

Inline static mixers or motionless mixers are available in a variety of styles for many different industries to handle countless applications. The Komax static mixer, known as the Triple Action Static Mixer, can be found in water/wastewater treatment, chemical industries, biofuels, oil and gas pipelines and custody transfer stations, mineral mining process, pulp and paper industries, desalination plants, food and beverage processing, plastics processing, power generation, and petrochemical industries.

Materials

The materials of construction for inline static mixers, as advised by the customer, are:

Plastics

- PVC

- CPVC

- Clear PVC

- Fiber glass or FRP

Lined

- PFTE

- Kynar-Teflon lined

- Teflon Lined

- Polyptopylene

Exotic/Special Alloys

- Chromalloy

- Alloy 20

- Monel 400

- Duplex 2205

- Super duplex 2507

- Titanium

- Titanium grade 2

- Hastelloy C276

- 600 alloy

- SA335 P11

Steel/Metal Alloy

- Stainless steel

- Carbon steel

- Low temp carbon steel (SA 333 GRD 6)

- Killed carbon steel, and ductile iron;

- Ductile iron

Applications

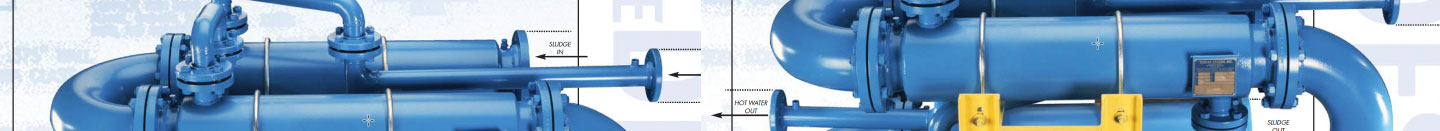

Water/Wastewater Treatment Industry

The Water/Wastewater industries use inline static mixers, wafer static mixers, non-clogging static mixers and channel mixers.

Applications

Typical applications seen in the water/wastewater industries are mixing of polymer, sodium permanganate, potassium permanganate, sodium hypochlorite, aqueous chemicals, alum, coagulant, chlorine, acid, aluminum sulphate, CO2 gas, NaOH, NaOCI, HCL, antiscalant, flocculant, oily sludge, polyelectrolyte.

Materials of Construction

Materials of construction include PVC inline static mixer, PVC Wafer Mixer, PVC non-clogging static mixer, CPVC static mixer, CPVC Wafer Mixer, clear PVC static mixer, FRP static mixer, FRP Wafer Mixer, FRP non-clogging static mixer, stainless steel static mixer, stainless steel non-clogging static mixer, stainless steel wafer mixer, carbon steel static mixer, carbon steel non-clogging static mixer, carbon steel wafer mixer, ductile iron static mixer, and ductile iron non-clogging static mixer.

Biofuel Industry

Typical applications and materials of construction for the biofuels industry are Teflon-lined static mixers.

Applications

Teflon-lined static mixers are commonly used to mix corn mash, sulfuric acid, stillage, beerwell, and other like fluids. You can also find Komax Teflon static mixers and Kynar-lined static mixers in the chemical, industrial, pulp and paper, plastics, power generation and food and beverage industries where sulfuric acids, caustic, flocculant, coagulant, resin, black liquor, hydrochloric acids, NACL, CL2, where corrosion resistant Teflon & Kynar lined static mixers are used for mixing concentrated acid or other aggressive chemicals.

Materials of Construction

Other lined static mixers Komax Systems offers are PFTE lined carbon steel static mixer, Kynar-Teflon lined static mixer, kynar lined static mixer, Teflon lined static mixer, Teflon lined carbon steel static mixer, Teflon lined carbon steel wafer mixer, Teflon lined carbon steel non-clogging static mixer, Teflon lined stainless steel static mixer and polypropylene static mixer.

Food & Beverage Industry

Unique to the food and beverage industry or any industry that requires CIP within their process pipeline you can find the Komax Sanitary Static Mixer. These Stainless-Steel Static Mixers are electropolished and can come as one unit or have removable elements for easy cleaning.

Applications

There is a wide variety of food and beverage applications from “solid” materials such as margarine, tomato pastes, Ketchup & Condiments, Mayonnaise, Jams & Jellies, Yogurt, fruit concentrate & Dairy Products to viscous liquids like syrups, peanut butter, batter, waffle batter, French fry batter, and light fluids similar to soft drink products, beer, vodka, vegetable oil, soybean oil, clear fat, flavor and coloring.

Oil & Gas Industry

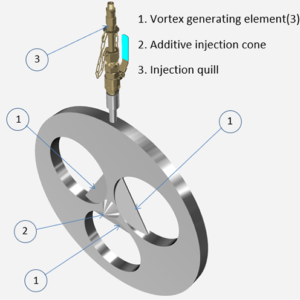

The Custody Transfer Static Mixer is specially designed to solve conventional custody transfer sampling and mixing problems in the oil and gas industry.

Applications

Komax Custody Transfer static mixers are installed in petroleum custody transfer sampling lines such as ship and tank truck terminals or refinery transfers in combination with a LACT unit where proper crude oil metering is an absolute must. The Komax Custody Transfer Static Mixer is installed upstream of the crude oil sampling transfer line.

End Connections/Options

- Flanged Ends

- Threaded Ends

- Plain ends

- DIN ends/connections available

- More available on request

Industries We Serve

See All IndustriesOur Product FAQs

If your questions about our products are not answered here, get in touch with us for more information.

See ALl FAQs