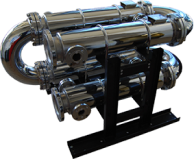

Stainless & Carbon Steel Static Mixers

Stainless Steel

Stainless steel is a versatile material that offers exceptional performance in high-temperature and highly corrosive environments. Its properties vary depending on the grade selected, allowing for tailored solutions to meet specific needs.

Whether it's resistance to rust and staining, durability, or ease of fabrication, stainless steel can be customized to suit the requirements of various applications. As a result, we are able to manufacture products such as stainless steel static mixers and custom stainless steel steam heaters using the most suitable grade of stainless steel for each task, ensuring optimal performance and longevity.

Carbon Steel

Carbon steel is a highly cost-effective material that can be easily manufactured in any size needed. Its versatility makes it suitable for use in a wide range of applications, with the ability to withstand temperatures ranging from 800 degrees Fahrenheit down to -49 degrees Celsius when utilizing A33 Grade 6.

While carbon steel can be used within almost any industry, it should be noted that it is not inherently resistant to corrosion. To combat this limitation, carbon steel is often paired with a corrosion-resistant material. Despite this requirement, carbon steel remains a popular choice for many applications due to its affordability and versatility. Carbon steel's ability to be easily produced in custom sizes makes it an attractive option for a variety of projects and can make products such as carbon steel static mixers.

Low Temp Carbon Steel/SA 333 GRD 6

Low temperature carbon steel, A333 Grade6, is a specialized material that offers exceptional performance in extremely cold environments. Unlike standard carbon steel, low temperature carbon steel can withstand temperatures as low as -49 degrees Fahrenheit, making it ideal for use in climates that regularly reach below -20 degrees.

This unique ability to operate in harsh conditions has made low temperature carbon steel a popular choice for use in piping systems of oil refineries. These piping systems are often exposed to the elements and require a material that can withstand the extreme cold without compromising the integrity of the pipes.

Beyond its use in oil refineries, low temperature carbon steel can also be used in a variety of other industrial applications that require high-performance materials that can withstand extreme cold temperatures. Its durability and resilience in low-temperature conditions make it a reliable choice for any project that requires a dependable material that can withstand harsh environments.

Killed Carbon Steel

Killed carbon steel is a specialized form of carbon steel that has been treated to reduce the risk of oxidation and improve its overall quality. This hard-wearing material is often used in applications where strength and durability are of utmost importance.

The term "killed" refers to the process of removing oxygen from the steel during processing, which leaves a low oxygen content in the metal. This process ensures that the carbon steel has low porosity, making it less susceptible to defects and other forms of damage.

Additionally, killed carbon steel has a more uniform composition, which can improve its strength and make it easier to machine and weld. These unique properties make killed carbon steel an attractive choice for a variety of industrial applications, including the production of machinery and equipment, structural components, and transportation vehicles. Whether used in high-stress environments or harsh weather conditions, killed carbon steel provides a reliable and long-lasting solution for many different industries.

Cement Lined Ductile Iron

Cement-lined ductile iron is a popular material used in water treatment and transportation due to its cost-effectiveness and ability to reduce corrosion susceptibility.

Ductile Iron has excellent tensile strength, bending strength and impact resistance making it resilient within an industrial piping system. The Ductile iron pipe, with coatings like cement, can be used in corrosive environments as well without eroding away over time. These factors significantly increase the service life of Ductile Iron materials increasing the efficacy and efficiency of the line’s process.

Additionally, cement-lined ductile iron is easy to install and maintain, making it a popular choice for water treatment facilities and transportation systems alike. With its unique combination of affordability, durability, and corrosion resistance, cement-lined ductile iron is a smart choice for any project that requires a reliable and long-lasting water transportation solution.