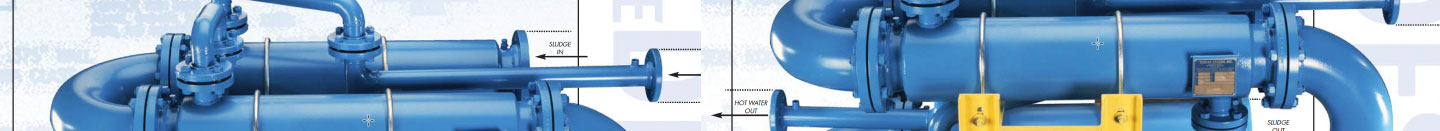

Industrial Steam Heaters

Our entire line of inline industrial steam heaters utilize our Equalizer™ Mixing Module, six cylindrical cavities equal in diameter that mount around the main pipe access. Each one contains its own helical mixing element. Once the steam is injected into the main line at the equalizer, the product and the steam come from the cavities, continually mixing in the same direction. The result? Multiple impingement mixing zones that finishes the process at a uniform temperature without the shock or vibration that so often accompanies the process. You don’t even need to add auxiliary air.

Industries We Serve

See All IndustriesOur Product FAQs

If your questions about our products are not answered here, get in touch with us for more information.

See ALl FAQs