Solutions for the Pulp & Paper Industry

The paper and pulp industry is a vital sector that involves the production of paper and paper-based products. The industry encompasses various processes, including pulping, bleaching, and papermaking, which require precise mixing and heating to ensure the production of high-quality products.

Mixing is an essential aspect of the paper and pulp industry, as it allows for the effective combination of chemicals and other additives into the pulp, ensuring efficient treatment and the production of high-quality paper. The heating of pulp and liquids during treatment processes is also crucial, as it helps maintain the ideal temperature, enhances the efficiency of the treatment and ensures the production of a high-quality final product.

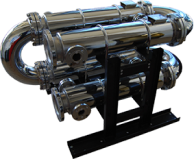

At Komax Systems we offer custom static mixers, steam heaters, & heat exchangers for the Pulp & Paper industry products that can help optimize the mixing and heating processes. Our products, such as inline static mixers, Inline steam heaters and heat exchangers, are designed to enhance efficiency, reduce energy costs, and guarantee the production of high-quality paper and pulp products.

Mixing and Heating Applications for Paper and Pulp Processing

Mixing Applications

Mixing is used to effectively mix chemicals and other additives into the pulp, which is essential for effective treatment and the production of high-quality paper. Some mixing applications are:

- Effective mixing of chemicals and additives: Inline static mixers can be utilized to thoroughly mix and distribute chemicals and other additives in the pulp, resulting in more effective treatment and a higher-quality final product.

- Accurate pH adjustment: Inline static mixers can be used to mix and distribute chemicals that adjust the pH of the pulp, ensuring that the pulp is at the optimal pH for treatment and the production of high-quality paper.

Heating Applications

The heating of pulps and liquids during treatment processes is also crucial, as it enhances the efficiency of the treatment and helps maintain the pulp and liquids at the ideal temperature. Some heating applications are:

- Bleaching optimization: Inline steam heaters can be used to heat paper pulps and liquids during the bleaching process, which enhances the effectiveness of treatment and reduces energy costs.

- Temperature control for pulp treatment: Heat exchangers can control the temperature of pulps used in paper and pulp production processes, ensuring that they are at the ideal temperature for effective treatment and reducing energy costs.

How Komax’s Products Help

Industrial mixing and heating are crucial aspects of the potable water treatment industry. Komax Systems' product offerings, such as inline static mixers and heat exchangers, provide solutions for the paper and pulp industry by enhancing the efficiency and effectiveness of treatment processes, ensuring the safety of water for human consumption, and reducing energy costs.

Related Case Studies

Pulp & Paper

Pulp & Paper