Custom Desuperheaters

Desuperheaters lower the temperature of (or attemperate) a superheated steam line using a cooling water source (typically a boiler feedwater (BFW)). The superheated steam or gas is directly in contact with the cooling water or fluid. Desuperheating immediately begins the process of evaporation and absorption into the steam line. Typically, enough water will inject into the line to bring the steam temperature down to around Saturation (+/- 10°F ). However, the desuperheaters can be used to more moderately attemperate the steam to a specified final temperature if desired. This is possible because Komax desuperheaters can operate with a turndown range of up to 20:1 with proper pressure control.

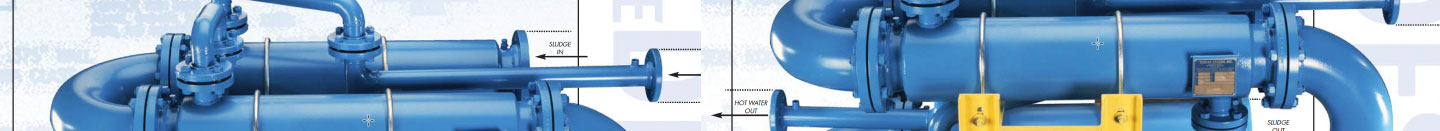

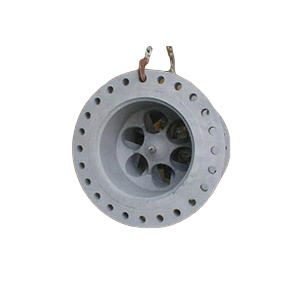

The Komax custom Desuperheater utilizes a unique approach to desuperheating compared to conventional desuperheaters. The Desuperheater uses both a low-pressure spray nozzle directed upstream of the steam flow and a patented Equalizer Mixing Module. We incorporate this into all of our desuperheater designs. This mixing module design is specifically for gas/liquid mixing and can shear the water droplets (or cooling fluid droplets) to very fine sizes.

Your Best Option

Wondering just what makes the Komax Desuperheater so good? Three stages of mixing, including our patented Equalizer™ mixing module within the desuperheater. Cooling happens almost instantly as it exits the mixing module, thus it doesn’t require the extensive downstream pipe lay length required by old-school designs. In fact, it needs less space, delivers more accurate temperature control, and reduces or eliminates thermal cycling fatigue in your piping, ensuring improved safety, less wear, and downtime. This makes for quick and efficient absorption of water into the superheated steam line.

There are no moving parts, and our steam desuperheaters offer high levels of consistency. Maintenance is never an issue as the low-pressure nozzle lasts and lasts. Almost no noise or vibration can be expected, and it’s a perfect fit for limited space.

Our patented Komax Desuperheater will exceed your expectations by increasing the efficiency and effectiveness of your gas desuperheating application at a price you can afford.

Fill out a RFQ form on our website today or contact Komax Systems, Inc. by phone at 800-826-0760, and you will speak to a dedicated Applications Specialist in your industry and be put in contact with the Local Komax Representative in your area.

Interested in better understanding the specification of our products for your current and future plants/contracts? Call us to schedule a Lunch and Learn Session!

Special thanks to Doug Tyler at Dakota Process.

Submit Your Request

Fill our out easy online form and get in touch with us!

Talk With Our Experts & Get a Quote!

Our experts will fine tune your quote to meet your projects specifications.

Get a Custom Design of Your Product

Get a sense of what your product will look like and how it will fit into your system.

Fabrication and Shipment of Your Order

Once approved we have the unit manufactured and shipped off to you!

Industries We Serve

See All IndustriesOur Product FAQs

If your questions about our products are not answered here, get in touch with us for more information.

See ALl FAQs