In-line Mixer Handles Tough Blending Job Tomato Paste and Water at 100 gpm

Food & Beverages Case Study

Citrus World, Florida’s third largest fruit co-op, recently expanded its product line to include tomato juices. In doing so, the Lake Wales based processor ran across a difficult blending problem.

Daniel Cronin, engineer on the project, says the co-op tried various vessels and mechanical mixing devices, in attempts to blend viscous tomato paste and water. None proved adequate, including side-and center-mounted agitators in holding tanks.

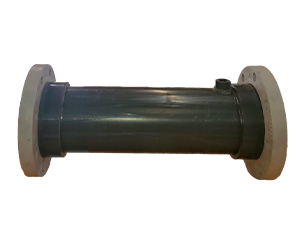

The solution turned out to be a Komax in-line static mixer . The 3-inch diameter, 42-inch long stainless steel mixer was installed vertically between holding bins and final blending tanks.

Says Cronin, “Using the mixer, we deliver a manageable, readily mixable solution to our blend tanks. Without the mixer, we could end up with blend tanks that stratified because the paste is so viscous, it won’t break up.”

With its successful tomato juice line, Citrus World has increased the output of its facility,and smoothed out the highs and lows of its orange juice lines.

The tomato juice process

Tomato paste arrives at the co-op in 300-gallon Scholle bins. These bins are wooden crates with a multi-layer of plastic in side, which keeps the paste aseptic.plastic in side, which keeps the paste aseptic.

Citrus World uses cold-break paste because it is less viscous than hot-break. Even so, the average viscosity of cold-break paste is 10,000 centipoise.

Paste is processed at a rate of 25-35 bins per day. The wooden bins are dumped into a 600-gallon holding tank. Then, the paste is transported with a positive displacement pump to the mixer.

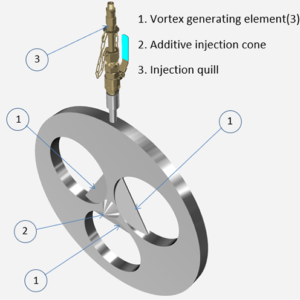

At the same time, water is pumped to the mixer via another positive displacement pump. An equal amount of paste and water meet in a 4-inch diameter blending line located directly in front of the mixer.

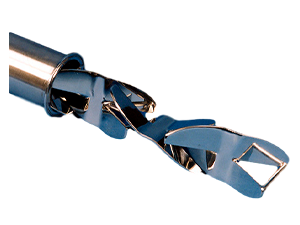

The mixer itself has a series of interlocking left-and right-handed elements. Under turbulent flow, these produce elliptical vortices, which rotate in opposite directions. In turn, these vortices produce a back-mixing effect that evenly disperses the paste and water. Flow rate is 100 gallons per minute.

The mixer also increases the velocity of the mixture. This action aids blending. The mixer is tapered at the ends; lines leading to and from the mixer are 4-inches, the mixer is 3-inches. This taper helps create a miniature Venturi effect.

Once through the mixer, paste and water solution is pumped to be the blend tanks. Here, salt, water, and other ingredients are added. After mixing, the juice is pumped to canning lines for packaging.

Right now, the tomato juice operation is small compared to orange juice. But it is expected to grow, and remain an important part of the product line.

Citrus World has the capacity for processing 125,000 boxes of citrus fruit per day. One box is the equivalent of 90 pounds of fruit. In 1981, the amount of citrus fruits processed by Citrus World represented about 30% of the total citrus crop of California in boxes, according to the co-op.

Principal product is orange juice sold in frozen concentrate form. To produce the juice, Citrus World has five evaporators which have the capacity to evaporate 250,000 pounds of water per hour. Finished concentrate is stored in a 3.5 million gallon capacity computer controlled tank farm. By storing concentrate in the tank farm for long periods, the co-op eliminates the need for large finished produce inventories. Juice can be held until customers specify the type and size of package.

How We Helped: Static Mixers

The solution turned out to be a Komax in-line static mixer . The 3-inch diameter, 42-inch long stainless steel mixer was installed vertically between holding bins and final blending tanks.

Says Cronin, “Using the mixer, we deliver a manageable, readily mixable solution to our blend tanks. Without the mixer, we could end up with blend tanks that stratified because the paste is so viscous, it won’t break up.”