Produced Water Treatment

Oil Sands Case Study

Komax Systems, Inc. is a mixing and systems engineering company. Over the years, Komax Systems, Inc. has demonstrated its expertise in hundreds of thousands of mixers in service. Komax Systems, Inc. mixing systems are installed in all fifty states, internationally and with over 40 years of successful operation.

Our know-how in custom Mixing By Designing and supplying mixing systems extends to virtually all market places including:

- Oil and Gas Industries

- Water/Waste Treatment

Below is just one example of how Komax Systems, Inc. provided an optimal energy efficient mixing solution to a client within your industry:

In 2009, Directive 074 was put in place by the ERCB (Energy Resources Conservation Board) in Alberta. This outlined specific criterion with timelines that Oil Sands operators needed to comply with the new Oil Sands Tailings regulations. At the same time our Water/Wastewater Treatment Applications Engineer received and inquiry regarding an application of mixing polymer with a clay slurry in an Oil Sands Settling Pond north of Fort McMurray. Known by industry leaders as Tailings Reduction or treatment this application called for a low cost, maintenance free, energy efficient way to speed up the reclamation process of the tailings ponds, a mixture of mostly clay and sand as a result of bitumen extract in the oil-up industry.

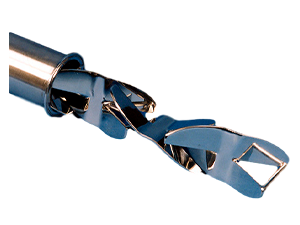

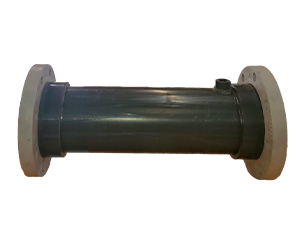

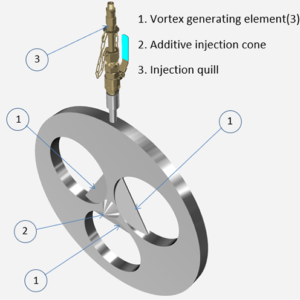

To mix the polymer with the clay slurry for the desired results Komax Systems, Inc. factored in the flow rates, density and viscosity to calculate and design the patented Hi-Pass™ Static Mixer. 12” in diameter made of Carbon Steel housing four (4) Hi-Pass™ mixing elements with an additive port.

The polymer was injected upstream of the Hi-Pass™ elements creating a shearing action with the clay slurry inducing a chemical reaction to effectively remove/treat their effluent tailings. Komax Systems, Inc. made by design with no fouling over 100 of these 12” Hi-Pass™ Static Mixers from 2009-2011 that were placed inline by this industry leading company to comply and pave the road to reduce tailing ponds and their carbon footprint.

Contact Komax Systems, Inc. by telephone or email today to discuss your tailings or water treatment application. Through continuous mixing Komax Static Mixers maximize fluid mixing and minimize energy consumption.

Call or email for your custom quote today!

How We Helped: Static Mixers

To mix the polymer with the clay slurry for the desired results Komax Systems, Inc. factored in the flow rates, density and viscosity to calculate and design the patented Hi-Pass™ Static Mixer. 12” in diameter made of Carbon Steel housing four (4) Hi-Pass™ mixing elements with an additive port.