Komax Teflon Lined Mixer Simplifies Acid Injection for Power Plant

Power Plant Case Study

A major source of waste water in many power plants is the waste stream that results from ion exchange used for demineralizing the boiler feed water.

The alkaline regeneration waste stream produced by the ion exchange process requires the addition of an acid to this stream before discharge from the plant. Regulatory authorities typically require the effluent to have a near neutral pH before disposal in the sewer system.

A Utah based energy company uses concentrated sulfuric acid (98%) to economically neutralize their demineralization waste stream.

Previously an expensive neutralization tank with a propeller mixer and a secondary “smoothing” tank with a propeller mixer was needed to mix and dilute the viscous concentrated sulfuric acid used for this neutralization process. These tanks covered 400 ft 2 of floor space and the mechanical mixers consumed 65,000 kw-hr annually.

Maintenance was estimated at $25,000 annually, as the high constantly fouled the pH probe, and the mechanical mixers required continual maintenance, and the tanks required annual cleaning due to the sludge that would build up in these tanks.

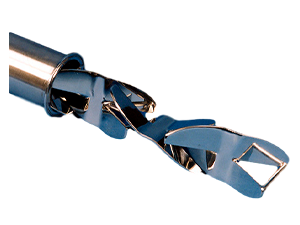

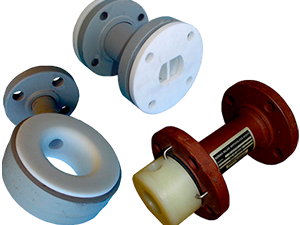

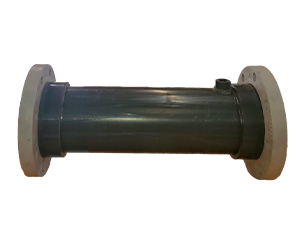

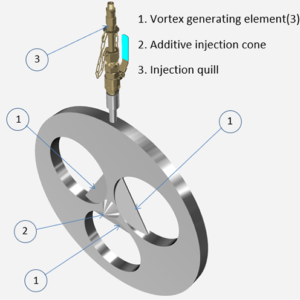

The neutralization tanks were replaced with a 3” Teflon lined in-line static mixer with optional injection port for direct injection of the sulfuric acid. The pH probe was placed downstream of the mixer, providing immediate feedback to the sulfuric acid dosing pumps.

This in-line static mixer saves energy costs, maintenance labor, reduces space requirements, and has achieved consistent control over the neutralization process.

How We Helped: Static Mixers

This in-line static mixer saves energy costs, maintenance labor, reduces space requirements, and has achieved consistent control over the neutralization process.