Custom Manufacturing

Worldwide Shipping

Reduced Costs

Energy Savings

Excellent Documentation

Our Clients:

Inline Static Mixer Manufacturer

Komax Systems leads the industrial piping industry offering agitating solutions, like static mixers, as well as a multitude of industrial heating solutions. We have been a manufacturer of static inline mixers, steam heaters, and heat exchangers since 1973 with our technologies being applied to projects worldwide.

Custom Products

Industries We Service

See All IndustriesFind Us At Our Upcoming Events

TappiCon 2024 | April 28 - May 1

Huntington Convention Center Cleveland Apr 28 - May 1In 1915, thirty enterprising papermakers gathered together determined to form a new technical arm of…

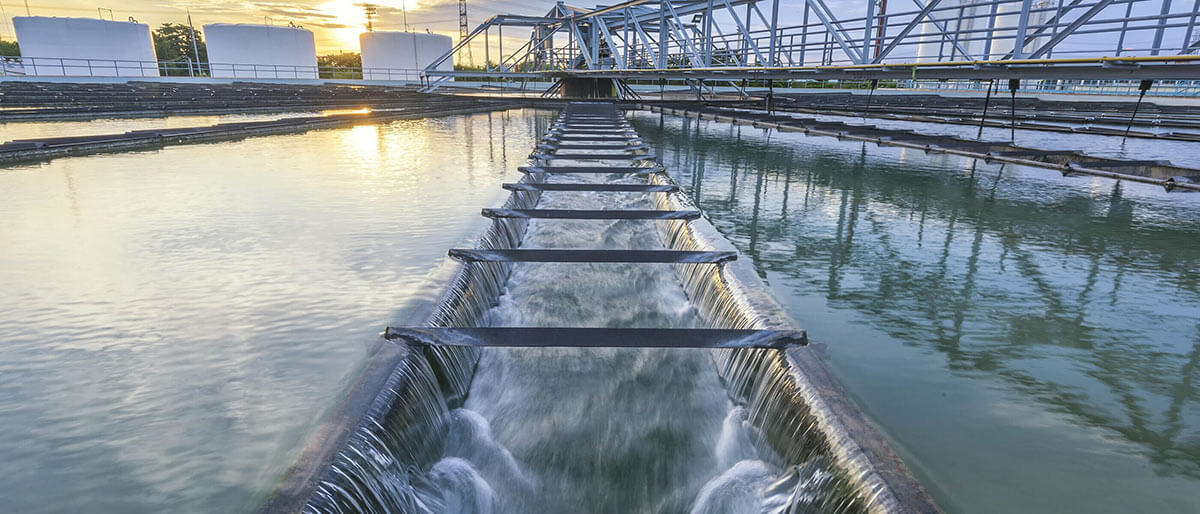

IFAT 2024 | May 13 - 17

International Congress Center May 13 - May 17From International Trade Fair for Sewage Technology to Global Network for Environmental Technologies.…

ISHM 2024 | May 14 - 16

Oklahoma City Convention Center May 14 - May 16ISHM advances knowledge and training of the hydrocarbon industry. The purpose of the ISHM School, with…

FEW International Conference 2024 | Fuel Ethanol Workshop & Expo

Minneapolis Convention Center Jun 10 - Jun 12Now in its 40th year, the FEW provides the global ethanol industry with cutting-edge content and unparalleled…

AWWA's 2024 ACE | American Water Work Association's ACE June 10 - 13

Anaheim Convention Center Jun 10 - Jun 12Water is the world’s most vital resource. There is no replacement. At ACE, we come together to discuss…

WEFTEC 2024 | Oct 5th - 9th

Ernest N. Morial Convention Center Oct 5 - Oct 9Whether you're a seasoned veteran or just starting out in the industry, WEFTEC is an essential gathering…

Frequently Asked Questions

If your questions about our products are not answered here, get in touch with us for more information.

See ALl FAQs