Komax Channel Mixer Replaces Mechanical Mixer at Mesa Val Vista WTP, Arizona

Water Treatment Case Study

Customer Issue: Movement of people and business to the Sunbelt areas of the U.S. has put pressure on many water utilities in those regions to expand their treatment plants. Jointly owned by the cities of Phoenix and Mesa, Arizona, the Val Vista Water Treatment Plant was one of those that underwent a modification program to increase its capacity.

In the original configuration, 7.5-hp mechanical mixers were used to disperse the chemicals into the stream through the 8-sq-ft flume joining the two basins. Two 4-bladed units were installed in parallel. While this method proved adequate for treatment of water at 80mgd, it was concluded that a new system would have to be installed to handle the uprated capacity.

Komax Solution/Innovation:

The firm selected to design the plant expansion, James M Montgomery, Consulting engineers, Inc. of Pasadena, California, studied several alter natives to the mechanical mixer then in service at Val Vista. Their work concluded that the static mixer manufactured by Komax Systems, Inc. of Long Beach would be preferred unit and would provide cost-effective, high efficiency mixing. The supplier was asked to custom-design a mixer which would fit into the eight-foot square channel.

Alternatives considered were determined to be either too expensive or inadequate. Mechanical mixers would have cost significantly more than the $30,000 price of the mixer chosen. Other baffle-type motionless mixing designs would have created too much head loss, and they were not available in a square configuration at that time.

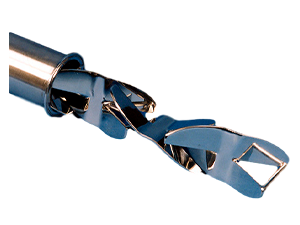

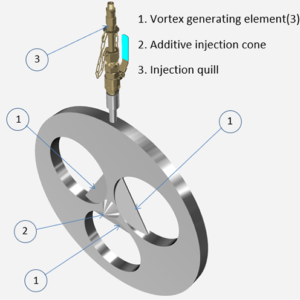

Installed in less than one week, the Komax mixer consists of a series of interlocking left- and right-handing mixing elements which, under turbulent flow, produce elliptical vortices rotating in opposite directions of either side of each element. The axis of each vortex is at right angles to the axis of the main water flow, producing a back-mixing effect that disperses the chemicals evenly. Chemicals are added through several spargers connected at the head of the mixer.

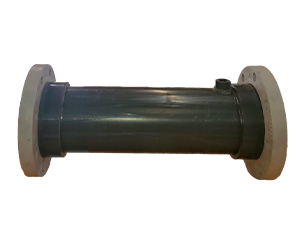

The 20-ft long unit, which has two mixing elements, is fabricated of carbon steel and bolted to the concrete channel. Treated with epoxy coating to resist corrosion, the mixer has a maximum head loss of 2 ft (under 1 psi) and a total effective mixing time of about 5 seconds at the maximum design flow rate of 140 mgd.

How We Helped: Static Mixers

Installed in less than one week, the Komax mixer consists of a series of interlocking left- and right-handing mixing elements which, under turbulent flow, produce elliptical vortices rotating in opposite directions of either side of each element.